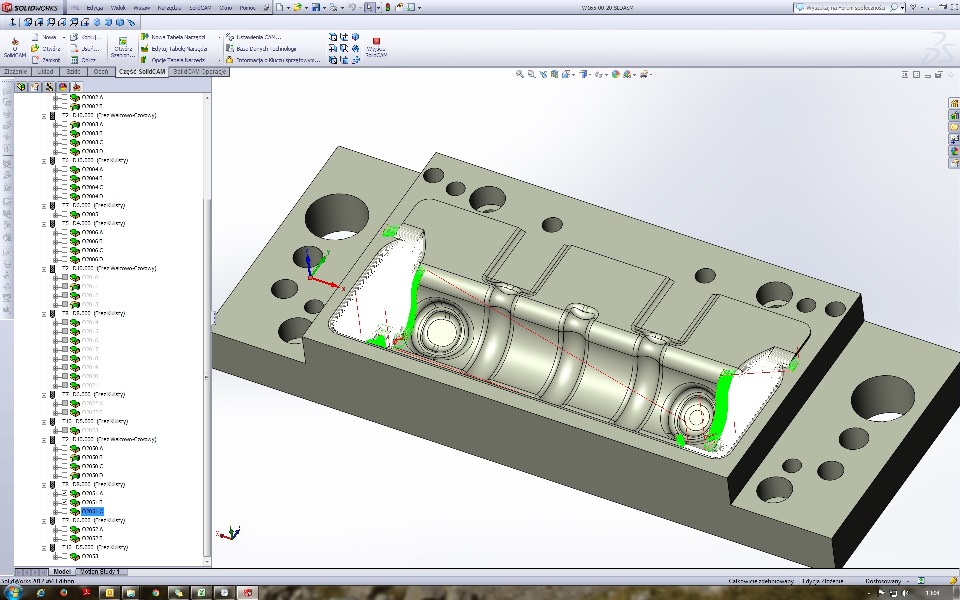

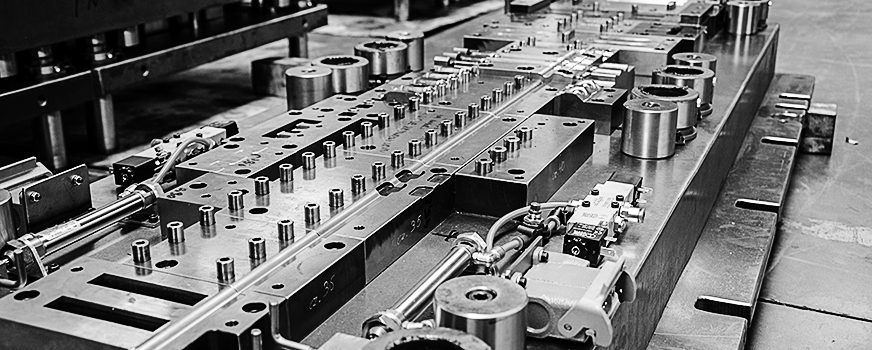

Most of the tools that we use at Hydrapres S.A. was built in our tool shop. Over the years of design and manufacturing, we have gathered vast experience that allow us to create the most advanced progressive tools. We can design and manufacture progressive dies of maximum length of 3200mm.

Photo: Progressive die.

The process of making tools consists of the following stages:

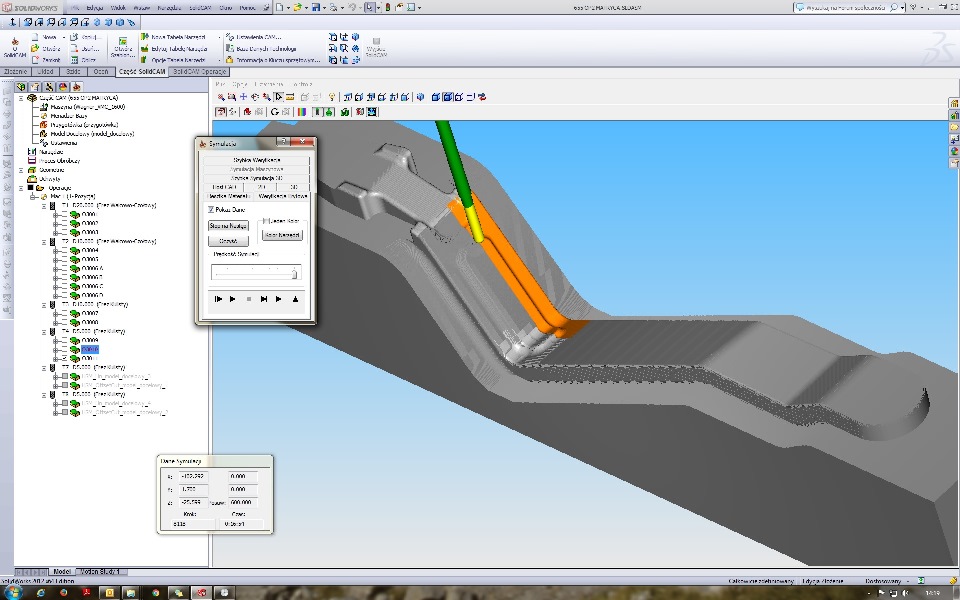

- project in Solid Works (3D modeling, 2D drawings)

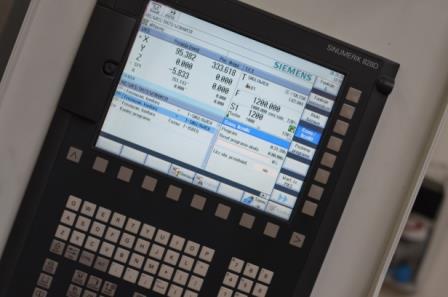

- manufacturing of tool elements

- measurement of tool elements

- tool assembly

- testing the tool

- measurement of parts made during tool tests.

Recently Hydrapres has invested in the development of our machine park, tool shop and machine construction. This allowed for a significant increase in processing capacity, and thus for timely and efficient service of new projects. Highly qualified staff of CNC operators ensures the highest quality of production. We have separate work stations for CNC programmers programming numerical machine tools (Solid CAM and PEPS).

.