Hydrapres designers develop the production technology and prepare the construction of tools. The entire die construction process is carried out in accordance with the APQP methodology. Projects are run by dedicated project managers. We specialize in the design of complex progressive dies. We have gained considerable experience in managing projects for the automotive industry. We manufacture, among others, elements of shock absorbers, safety systems, drives, seats and gearboxes as well as components for the electronics and furniture industry.

CAD / CAM software suppliers we use:

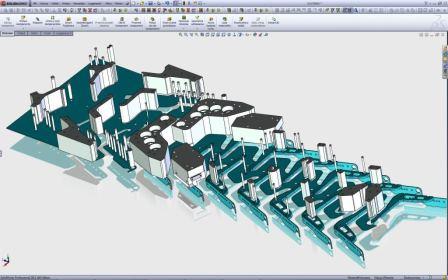

Working with CAD programs helps the designer in modelling the final version of the tool,and also prevents errors by constant monitoringover the entire assembly.

Examples of parts can be seen here.

The design office is supported by CNC programmers who prepare programs for milling and WEDM machines.